What Is a High Pressure Sodium (HPS) Lamp

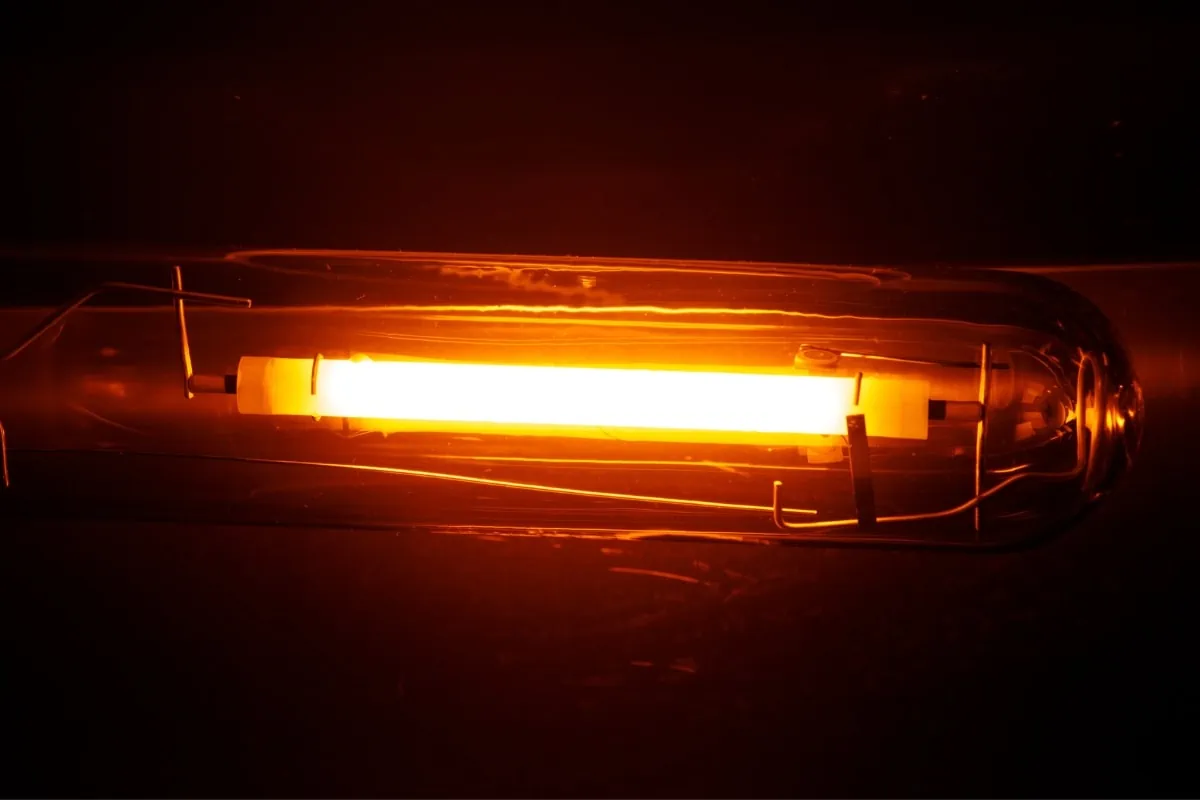

A High-Pressure Sodium (HPS) Lamp is a type of gas-discharge lamp. It is a form of high-intensity discharge (HID) lighting that generates light energy by passing an electric current through a mixture of mercury vapor and sodium vapor. The lamp consists of a sealed glass tube containing these gases, along with electrodes at each end.

When the lamp is turned on, an electric current is applied to the electrodes, creating an arc of electricity between them. This arc heats up the gases inside the tube, causing them to emit light. The mercury vapor emits ultraviolet (UV) light, which then excites the sodium vapor, resulting in the characteristic yellowish-orange light emitted by HPS lamps, which gives HPS lamps their distinctive yellowish light.

HPS lamps are widely used in outdoor lighting applications, such as streetlights, parking lot lights, and security lighting. They are valued for their high efficiency and long lifespan. HPS lamps produce a large amount of light output per watt of energy consumed, making them an energy-efficient choice for various lighting needs.

While newer lighting technologies such as LEDs and ceramic metal halide (CMH) are providing competition for HPS lamps, they still remain an important lighting option in various applications. The popularity of HPS lamps in street lighting and security lighting, their energy efficiency, long lifespan, and ability to provide high-quality illumination make them an important choice in the lighting industry.

How a High Pressure Sodium Lamp Works

A HPS lamp works by passing an electric current through a mixture of gases and vaporized sodium. The lamp consists of a sealed glass bulb containing a discharge tube, electrodes, and a small amount of sodium. When the lamp is turned on, an electric arc is created within the lamp, which heats up the gases and vaporizes the sodium. The sodium vapor emits light when it is excited by the electric arc.

The arc tube in an HPS lamp is made of a heat-resistant ceramic material, such as aluminum oxide, to withstand the high temperatures generated by the electric arc. The arc tube also contains a starting gas, typically xenon, which helps initiate the arc when the lamp is turned on.

Once the arc is established, the electric current causes the sodium metal to vaporize, releasing sodium atoms into the arc. These sodium atoms become excited by the energy from the electric arc and emit light as they return to their ground state. The emitted light has a characteristic yellowish color due to the dominant emission of sodium vapor at a specific wavelength.

The lamp’s outer glass envelope helps to protect the arc tube and provides thermal insulation. It also filters out harmful ultraviolet (UV) radiation emitted by the arc, ensuring that only visible light is emitted.

HPS lamps require a ballast to regulate the electrical current flowing through the lamp. The ballast helps to start the lamp and maintain a stable operating condition. It also ensures that the lamp operates at the correct voltage and current levels.

Advantages of High Pressure Sodium Lamps

HPS lighting offers several advantages that make it a popular choice in lighting fixtures. Here are some of the key advantages.

Energy Efficiency (Compared to Traditional Bulbs)

HPS lights are known for their high energy efficiency. They produce a large amount of light output per watt of electricity consumed, making them a cost-effective lighting solution. This efficiency is especially beneficial for outdoor lighting applications, such as streetlights and parking lot lights, where large areas need to be illuminated for extended periods.

Grow Light

HPS lamps are widely used in horticulture as grow lights. They emit light rich in the red spectrum, which promotes plant growth and flowering. The yellow to red light spectrum emitted by HPS lamps mimics natural outdoor conditions, making them suitable for indoor gardening. HPS lights are favored during the reproductive and vegetative stages of gardening, as they provide the necessary light spectrum to enhance plant growth and prevent plants from growing overly spindly and long.

High Light Output

HPS lights emit a bright, warm-colored light that is ideal for outdoor applications. The yellow-orange light produced by HPS lamps enhances visibility and provides good color rendering, making it suitable for areas where accurate color perception is not critical, such as street lighting or industrial facilities.

Warm Yellow Hue

HPS lamps emit a warm yellow hue, which is often preferred for outdoor lighting applications. This warm color temperature enhances visibility and creates a pleasant ambiance. It is particularly suitable for streetlights, parking lot lighting, and other outdoor areas where good visibility and safety are essential.

Cost-Effective

HPS lighting is generally more affordable compared to other lighting options, such as LED or metal halide. The lower initial cost of HPS lamps, combined with their energy efficiency and long lifespan, makes them a cost-effective choice for various applications, particularly in outdoor and industrial settings.

Suitable for High-Intensity Applications

HPS lighting is well-suited for high-intensity applications where a substantial amount of light is required. It is commonly used in outdoor areas that require bright illumination, such as highways, sports fields, and industrial facilities. The high light output and efficacy of HPS lamps make them an efficient solution for these demanding environments.

Reliable Performance

HPS lamps are known for their reliable performance, even in challenging conditions. They can withstand temperature variations, vibrations, and other environmental factors, making them a dependable lighting option for outdoor and industrial applications.

Good Color Rendering

High-pressure sodium lamps have a relatively high color rendering index (CRI) compared to other HID lamps. While not as high as some other lighting technologies like LED, HPS lamps still provide reasonably good color rendering, allowing objects and surroundings to be perceived with a reasonable level of accuracy.

Compatibility and Easy Installation

HPS lamps are compatible with existing lighting fixtures, making them a convenient choice for retrofitting projects. They can easily replace older, less efficient lighting technologies without the need for extensive modifications. This simplifies the installation process and reduces installation costs.

Disadvantages of High Pressure Sodium Lamps

High pressure sodium lighting, while widely used in various applications, does come with its fair share of disadvantages that should be considered. Let’s take a closer look at some of the drawbacks of using HPS lighting.

Limited Color Rendering

One of the main disadvantages of HPS lighting is its limited color rendering capabilities. HPS lamps produce a yellowish-orange light, which can distort the perception of colors. This can be problematic in applications where accurate color representation is important, such as in retail stores or art galleries. Compared to other lighting technologies, HPS lights have a relatively low color rendering index (CRI), which measures how accurately a light source renders colors compared to natural light.

Warm-Up and Restrike Time

HPS lamps require a warm-up period before reaching their full brightness. This warm-up time can range from several minutes to even half an hour, depending on the lamp type and wattage. Additionally, if the power supply is interrupted, HPS lamps have a restrike time, meaning they need to cool down before they can be turned back on. This delay can be inconvenient in situations where immediate lighting is required.

Bulky Size

HPS lamps tend to be larger and bulkier compared to other lighting options. This can make them less suitable for applications where space is limited or where a more compact lighting solution is desired.

Limited Dimming Options

HPS lamps are not easily dimmable compared to other lighting technologies. Dimming options for HPS lamps are limited and may require additional equipment or specialized control systems. This can be a disadvantage in applications where flexible lighting control is desired.

High Energy Consumption

HPS lighting is relatively energy-intensive compared to newer technologies such as LED lighting. While HPS lamps are more energy-efficient than traditional incandescent bulbs, they are less efficient than LED lights. This higher energy consumption can result in increased electricity costs, especially in applications where lighting is required for extended periods.

Maintenance and Lifespan

HPS lamps have a limited lifespan compared to some other lighting options. On average, HPS lamps last around 15,000 to 24,000 hours, depending on the specific lamp and operating conditions. This means that they may need to be replaced more frequently, resulting in additional maintenance costs and inconvenience.

Heat Output

HPS lamps generate a significant amount of heat during operation. This can be a disadvantage in certain applications where heat management is critical, such as in small enclosed spaces or areas with sensitive materials. The excess heat can also contribute to higher cooling costs in indoor environments.

Environmental Impact

HPS lighting contains small amounts of mercury, which is a toxic substance that can be harmful to the environment if not disposed of properly. While the amount of mercury in HPS lamps is relatively small compared to older technologies like fluorescent lamps, proper recycling and disposal methods should still be followed to minimize environmental impact.

Glare and Light Pollution

HPS lighting can produce glare, which refers to the visual impairment caused by a bright source of light. Glare can be discomforting and can affect visibility, making it difficult to see clearly. This can be particularly problematic in outdoor settings where HPS lamps are commonly used, such as street lighting. Additionally, HPS lamps contribute to light pollution, which can negatively impact the natural environment and disrupt ecosystems.

Frequently Asked Questions

Can I Replace My High Pressure Sodium Bulb With LED

LEDs are a more efficient option for lighting as they have better light control. This means that you can replace a higher-watt high pressure sodium bulb with a lower-watt LED. One disadvantage of high pressure sodium lighting is its yellow hue, which can distort the true appearance of objects.

What Can I Use Instead of High Pressure Sodium Lights

LED lighting is a suitable alternative to high pressure sodium lights. LED lights have a higher Color Rendering Index (CRI), which means they provide brighter illumination compared to HPS lights. Additionally, LED lights can compete with HPS lights even though they are typically lower in wattage than metal halide lights.

Do High Pressure Sodium Bulbs Need a Ballast

HPS bulbs require a ballast in order to function properly. This means that if you want to change the wattage of the bulb or fixture, you will also need to change the ballast. You cannot simply switch out the bulb without considering the ballast. Therefore, it is necessary to stick with your current bulb unless you also change the ballast.

Do Sodium Lights Use a Lot of Electricity

High-pressure sodium lamps are known for their efficiency in terms of electricity consumption. When measured for photopic lighting conditions, they can produce about 100 lumens per watt. It is worth noting that some higher-power lamps, such as the 600-watt ones, have even higher efficacies of around 150 lumens per watt.