The range of available fire extinguisher types (their size, color and method of operation) is so wide as to create some degree of confusion. All guidance on this area states that the equipment which could be used by the average person in a fire situation should be both suitably located and suitable for the risk.

However, problems can arise when more than one type of fire risk is encountered and the pressurized person is faced with a choice of the extinguisher. The wrong choice could mean firefighting efforts are wasted or place the individual under even greater risk.

The fire extinguisher types available correspond heavily to the nature of the risk. Fires are classified into five main types, and the ability of a fire extinguisher to deal with a specific classification depends on the agent within it.

Classification of Fires

Class A – Fires that involve mainly organic solids (containing carbon based compounds) such as wood, paper, plastics, etc.

Class B – Fires that involve flammable liquids such as petrol, paint and oils, and liquefiable solids such as fats, waxes, and greases but not including cooking oil or fats

Class C – Fires that involve gases such as butane or propane

Class D – Fires that involve certain metals such as sodium, magnesium and aluminum

Class F – Fires that involve commercial deep fat or oil fryers

How Fire Extinguishers Work

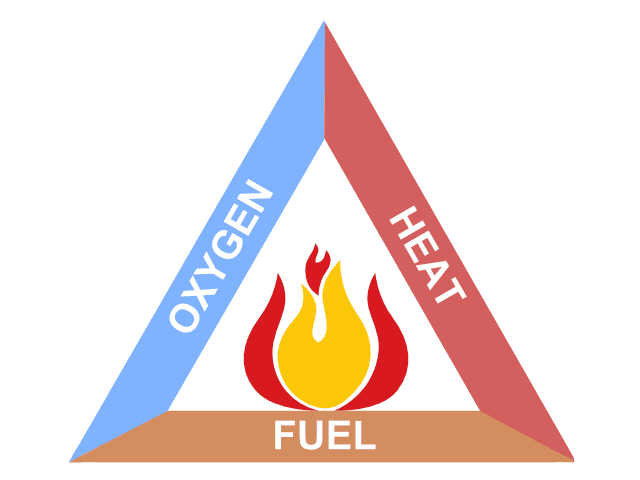

It is basic knowledge that for a fire to occur, three things are required – Heat, oxygen (or similar gas), and fuel. Remove one of the three elements, and the fire will die. A fire extinguisher is designed to do just that. Different fire extinguisher types will remove different elements of the fire; however, the effect is still the same.

All fire extinguisher types have some form of lever at the top of the canister, which expels the agent inside it by high pressure. For this reason to avoid accidental spillage, the levers of fire extinguishers are fitted with a pin that must be pulled out in order for the extinguisher to be used.

When the lever is compressed, this pushes into a connecting rod inside the extinguisher, which in turn presses into a spring-mounted valve, opening up the passageway to the exit nozzle.

The bottom of the connecting rod has a sharp point, which when forced downwards, pierces a gas cylinder release valve inside the extinguisher. The released gas itself then puts pressure on the extinguishing agent inside the cylinder, so that it is driven upwards through a siphon tube to the exit nozzle with some considerable force. The extinguishing agent should be aimed at the fuel of the fire rather than the flames themselves in order to put the fire out.

Class D Fire Extinguisher

Class D fire extinguishers are a specific, specialist type of fire-suppressant derived from the dry powder extinguishers used on Class A, B and C fires, used solely for the purpose of extinguishing Class D fires. These fires are caused by burning metals that combustion reaction with the air.

Due to the very specific nature of this type of fire, the portable extinguisher used to tackle their needs to be very special too.

Class D fires are caused by processes involving various metals in manufacturing or scientific laboratories, such as cutting, drilling or mining, and often only a very small amount of metal dust (or swarf) can cause a combustion.

Industries where this type of fire is a significant risk have to take special precautions so that the risk of fire is limited. The types of metals that can be involved in Class D fires are sodium, lithium, magnesium, potassium, steel and others. Magnesium and titanium fires in particular, are more common than would be thought as they are often used in the batteries of computers. When a combustible metal ignites, it can easily spread to other combustible materials around it.

Aside from those metals that combust with air or water, combustible metals are not a large fire risk in larger pieces as they are generally unable to maintain the heat of a combustion, so a lot of heat is required to maintain the fire. Usually in the case of a fire involving a laptop battery, for example, the combustible metal starts the fire which is spread and maintained by the other combustible materials around the starting point.

What Is a Class D Fire Extinguisher Made Of

A Class D extinguisher has a specialist chemical makeup and application as well as that of its fire fighting capabilities. The extinguishing agent absorbs the heat and smothers the flames, which restricts the oxygen, thus putting out the fire. Like ordinary dry powder extinguishers, a Class D fire extinguisher is red in color with a band of blue located in the top half of the canister which covers no more than 5% of the body. This kind of specialist extinguisher will have some kind of indication on the label that it is designed for Class D fires so it can be identified.

These extinguishers will also be equipped with a long hose and usually a rounded lance style applicator to allow the operator to keep well back from the fire and allows for easy application of the chemical powder. The applicator is designed so that the chemical will be applied at a low velocity, so it will land efficiently and effectively onto the fire, preventing any swarf from spreading. The canisters of a Class D extinguisher usually come in a 9kg size, which makes them heavier than some but effective for the type of fire to be dealt with.

Different compositions of the chemical within the canister will have a limited effect on the composition of certain fires. For example, a copper powder variety will have limited effect on a lithium fire. For this reason, the exact specification of the dry powder must be considered when a Class D fire extinguisher is placed.

The extinguishing agent, when released, can affect the health of a user or individual in the vicinity, so a Class D fire extinguisher should never be used in a confined space. Due to the nature of this extinguisher, those located near one should be suitably trained in using this specialist piece of portable firefighting equipment.

Dry Powder Fire Extinguisher

Dry Powder fire extinguishers are the most versatile portable fire suppressant available on the market and are suitable primarily for Class B or Class C fires (although only on small liquefied gas fires that belong to Class C).

Dry powder can also be used on Class A fires if necessary but it is not the best type of extinguisher for that class. Specific dry powders are also available for certain situations, such as metal fires or for use in the motor industry.

Dry powder is also a good choice for fires involving electricity. However if the fire involves computers or other delicate machinery, CO2 is a better choice as it does no damage to the equipment. Dry powder leaves a sticky and corrosive residue behind that could cause damage.

A dry powder fire extinguisher is identifiable from other types by the blue band on the upper half of the canister covering less than 5% of the total surface. The rest of the surface of the unit is bright signal red, the same as other types. A pressure gauge will be present towards the top of the unit, near the trigger and nozzle. There will always be a nozzle to direct the extinguishing agent, but larger models (usually any with a weight of 3kg or more) will come equipped with a hose to allow better control over the direction of the dry powder.

Most dry powder canisters come in three different sizes – 1kg, 2kg and 6kg, although 12kg is also available. The size of the canister is dependent on the fire risk in the area in which it is installed.

Smaller models are ideal for the home and small offices or workshops, or even cars. This type of extinguisher is also suitable for storing in colder environments such as garages or outhouses, as they are capable of operating between the temperatures of -30°C and 60°C.

These types of extinguishers are filled with an inert chemical powder and pressurized by a gas (usually nitrogen). Different powders can be used, most commonly Monoammonium phosphate or Sodium bicarbonate. The powder works on release through a chemical reaction with the fire, which causes the particles to expand, inhibiting the combustion and eliminating the oxygen, causing the fire to die.

How to Use a Dry Powder Fire Extinguisher

Using a dry powder fire extinguisher requires some skill as the technique is different from using some other types of extinguishers, and individuals should always be trained in using one if the extinguishers are present.

For fires involving liquids in containers or spilled liquids, the nozzle needs to be directed at the near edge of the fire, and a rapid sweeping motion of the nozzle applied gradually towards the far edge.

On fires involving flowing liquids, the nozzle should be directed at the base of the flames and swept upwards. If electricity is involved (or suspected), the main supply must also be shut off before any attempts to tackle the fire are made.

Dry powder extinguishers should never be used in confined spaces, as the chemical reaction caused by using it removes oxygen and has been known to do the same to the human lungs, which can cause asphyxiation. In extreme cases, this reaction can also cause cardiac arrest. Cases of death caused by usage of a dry powder fire extinguisher are very rare, however, and should not count against an otherwise excellent multi-purpose extinguishing agent.

Wet Chemical Fire Extinguisher

Wet chemical fire extinguishers are a relatively new addition to the world of portable fire suppressants, designed solely with the purpose of fighting deep fat cooking fires (which involve animal fat or vegetable oils). No other extinguisher can do the job they do. They are such an innovation that a separate class of fire, Class F, was created for the classification of deep fat cooking fires, and a new British Standard, BS 7937:2000 had to be written for them.

The original model of this type was created by Chubb, although there are now many others available on the market.

This type of fire extinguisher usually comes in a 6 liter size, which means it is easy to handle, and the extinguishing agent is so effective it is able to tackle a 75 liter fat fire, even if the temperature of the burning fat is at 340 degrees.

Different sizes of canisters will suit different size capacity fryers, so the right size should always be purchased. The wet chemical has a saponification effect that creates a thick foam, which smothers the oxygen supply to the fire and prevents it from re-igniting. The chemical will cool the fat but not instantaneously. It needs to be left to do so for a short while.

Often a slightly different shape to other extinguishers, and easily identifiable by the band of bright yellow somewhere in the upper half of the canister, the majority of wet chemical extinguishers have a long, thin hose and nozzle applicator as the exit route for the agent. This allows the operator to keep well away from the burning fire (in case of any splashback, which although very unlikely with this type of fire-suppressant, could cause great harm).

The method used to apply a wet chemical fire extinguisher is different to that of other types, so individuals located in an area where this agent is present should be suitably trained in using it. It is fairly common to see wet chemical fire extinguishers located alongside CO2 ones, particularly in industrial kitchens or restaurants.

How to Use a Wet Chemical Fire Extinguisher

When applying a wet chemical fire extinguisher onto a fire, the hose and nozzle should be held at arm’s length and applied in slow, circular movements. The resulting mist of chemical may appear too gentle a method to look like it would be effective. However, this fine spray covers the greatest area possible to the burning fat, before the chemical turns it into a foamy substance, sealing and extinguishing it.

Wet chemicals should always be applied with great care since smoke and fumes can result. Of course, wherever possible, the source of the heat should be turned off before any attempt to tackle the fire is begun.

Although a wet chemical fire extinguisher should not be used on a fire involving live electricity, it does possess a safety feature in that the nozzle has passed the BSi 35kv conductivity tests, so if electrical items are accidentally sprayed in a fire situation, the operator of the extinguisher will not be harmed.

If necessary, a wet chemical extinguisher can also be applied to a Class A or Class B fire, if a more suitable extinguisher is not available at the time, which makes it a very versatile product.

Water Fire Extinguisher

By far the most popular choice in portable fire suppressants is water. Ideally suited for ordinary combustible fires known as the Class A category, water fire extinguishers are the most effective suppressing agent for fires involving paper, wood, fabrics and furnishings, which are the most common material components of household fires.

This type of extinguisher is popular for several reasons. They are very simple to use, easy to refill and the contents are not harmful to people or the environment. For these reasons, they are often found in settings where children and young people are present.

Despite the obvious advantages to a water fire extinguisher, they must never be used in fires where live electricity is present or could possibly become exposed, as water conducts electricity. CO2 extinguishers are better suited to this type of fire.

A water fire extinguisher is also not recommended for Class B or D fires, as the power of the water from the nozzle is more likely to spread the burning materials over a larger area and make the fire worse, rather than actually extinguishing it.

What Color Is a Water Fire Extinguisher

Water fire extinguishers are solid bright red in color, and unlike other portable fire extinguishers, they have no band of any other color across them. Some premises have stainless steel versions with red lettering instead, although this is more of a design choice and these do not conform to the requirements of BS EN3.

All water fire extinguishers have a black hose and nozzle attached, so the fire can be accurately tackled directly by the operator. A pressure gauge is also present by the handle of the canister, which gives the user or the individual performing maintenance and servicing a clear view of whether or not the amount of water inside is sufficient for use in a fire.

This type of extinguishing agent attacks a fire in two ways simultaneously – firstly by dousing the flames and also by soaking the materials fuelling the fire so that they are unable to continue burning. The canisters can come in several ratings (which display the maximum volume of combustible materials the extinguisher can handle), with the most common being 13A, and the best being 21A. Water has a limited capacity in fighting a fire, and as the majority of canisters carry 9 liters, they are also usually heavier than the majority of other types of extinguishers.

It is becoming more common for organizations to purchase water extinguishers that have additives in the liquid. A 3 liter water additive canister has the same 13A rating as a 9 liter water version. The additives work by making the water ‘stickier’ than normal, so it can stick to and soak the burning material more effectively. There are also some components in the additives that make this type of extinguisher similar to the ingredients in foam extinguishers.

Water additive extinguishers can also be used on electrical fires if the nozzle is kept more than 1 meter away (although it is always ideal to isolate any electrical system before using this type of extinguisher). As these extinguishers are lighter, this makes them easier to lift and operate, although traditional water canisters are far from becoming obsolete yet.

Foam Fire Extinguisher

Foam fire extinguishers are a reasonably popular type of portable fire-suppressant for multi-risk situations. They are normally used to tackle flammable solid fuel and liquid fires of Class A and Class B types – these are fires fuelled by wood, paper and textiles as well as flammable oils, petrol, spirits, etc.

Foam will also have some effect on Class C fires that involve liquefied gas. Typical foam fire extinguishers are also known as AFFF (Aqueous Film Forming Foam) or spray foam fire extinguishers, and are a water-based synthetic foam, usually containing sodium alkyl sulfate.

These extinguishers are certainly more efficient than some other types, as the foam used is non-toxic, does no damage to most materials, is not expelled from the canister violently and prevents any re-ignition. Foam extinguishers work by quickly forming a blanket over the surface of the burning fuel, which cools and smothers the fire, preventing any oxygen from re-igniting.

It is common to see a foam extinguisher in both business use and in the home, as they are suitable for offices, boats, caravans, kitchens and similar premises. Fire fighting services also occasionally use foam as a fire suppressant due to its efficiency at putting out larger-scale fires.

Foam fire extinguishers are equipped with a spray nozzle to direct the material across a wider area. Use of a foam extinguisher requires some skill, as in order to use it most effectively requires the user to aim the spray firstly at the rear of the fire and lay the foam across the surface.

A foam fire extinguisher is not suitable for usage on electrical fires. However, extra testing has proved that there is some protection offered to the user of a foam extinguisher in a situation where it is used accidentally on an electrical fire. Despite this, foam extinguishers are not recommended for electrical fires as it is still possible for the operator to obtain an electric shock if they are positioned in a puddle and the electrical circuit does not short circuit.

What Color Is a Foam Fire Extinguisher

Foam fire extinguishers are color-coded red with a cream band across the top half of the canister which can be no larger than 5% of the size of the canister. This type of extinguisher can come in many sizes from 2 liters upwards, and due to the effectiveness of the contents, a 6 liter foam extinguisher has the same coverage as the equivalent of a traditional 9 liter water extinguisher.

This size reduction is part of this type of extinguisher’s popularity, as it makes the canister easier to handle and means it takes up less size. The canisters will be fitted with a nozzle with spray attachment, and the size of the nozzle will correspond to the size of canister.

Foam fire extinguishers should be wall-mounted at about a meter high, or if the wall cannot support the weight, should be fitted to a stand. The cream-colored labels must be easily visible in case of emergency in order to be used quickly by the operator. There must also be suitable signage mounted on the wall next to the extinguisher to mark clearly that this is a foam fire extinguisher situated there.

Halon Fire Extinguisher

There was a time when Halon fire extinguishers were very popular as an extinguishing agent for fires involving computer equipment and high-tech facilities. This type of portable extinguisher contained Halon 1211 (pronounced as twelve-eleven), which was useful as it vaporizes, leaving no residue behind, so it would not damage delicate computer equipment during usage, but could also be used effectively on any type of fire. Halon works by stopping the chemical reaction of the fuel involved in the fire when it ignites and burns, as well as smothering the oxygen in a similar way to CO2.

However, it was discovered in the 1980s that Halons had the highest level of ozone depletion out of any chemical in common usage. When over 150 countries signed up to the Montreal agreement in 1987, which meant that they would agree to control ozone-depleting chemicals, Halon became one of the first substances to be banned in 1993.

As a Halon fire extinguisher can only be refilled using recycled Halon, the EU decided in 1999 that all Halon fire systems (including Halon 1301 used in fixed systems and Halon 1211 in portable systems) would be decommissioned, a ruling which was fully implemented in the UK by the end of 2003. It is worth noting that Halon is still used as a fire suppressant in many other countries around the world, especially in countries that did not sign up to the Montreal agreement and the following Kyoto agreement.

A Halon fire extinguisher that is still on a site should be immediately decommissioned and taken to a local civil amenity site (not all sites have facilities for them so always contact your local council first). It is illegal to dump or discharge a Halon extinguisher as well as owning one.

However, there are circumstances where usage of a Halon fire extinguisher is still legally acceptable but also very tightly controlled. These three circumstances are: in aircraft, for military use and in the channel tunnel. The latter, for example, has a fixed suppression system fuelled by Halon 1301. The reasoning for these exemptions are primarily due to the lack of a viable alternative, particularly as in cases of fire in these locations could be devastating and cause much loss of life.

What Color Is a Halon Fire Extinguisher

Older Halon fire extinguishers are green in color, similar to that of British racing green, however not all of this type of extinguishers look the same. Halon extinguishers operated by the military are dark bottle green, those owned by British Rail were yellow and some others had them yellow and gold. Newer Halon models can be bright red with a green band.

However, one thing they all have in common is that they will all be clearly marked with a label stating the contents. In design these extinguishers look similar to many others as they have a similar nozzle and trigger operation.

Due to the strict regulations involved in owning and operating a Halon fire extinguisher, most suppliers will obviously be unable to sell them. A popular and easy replacement for Halon has been CO2 extinguishers, which essentially do the same job but are much safer for the environment.

CO2 Fire Extinguisher

Carbon dioxide fire extinguishers are filled with non-flammable gas under high pressure. These are primarily used for Class B fires (flammable liquids that are miscible with water) and electrical fires. The CO2 fire extinguisher is a popular choice of portable fire-suppressant as they became a natural replacement for Halon ones when they were taken out of general use.

This type of fire extinguisher can be identified in several ways. Older versions will be black in color, while newer versions will be red with a black logo somewhere near the top of the canister.

CO2 extinguishers have no visible pressure gauge and the exit nozzle is distinguishable as it is a large black horn. They can vary in size from 5lbs to 100lbs or more, and the horn in larger sizes will be attached to a flexible hose.

In a fire where electricity is involved, carbon dioxide is the best choice of extinguisher. Unlike dry powder, it leaves no residue behind, so it does no damage to equipment such as computers and photocopiers.

The gas is capable of entering the body of the equipment involved and thus putting out the fire. It is also often used in restaurants (for Class F fires not involving deep fat cooking fires) as it will not contaminate food or cooking equipment. CO2 is not suitable for Class F fires as it has such a powerful discharge that it could cause a splashback of the hot oil onto the operator.

Other locations where a CO2 extinguisher is suitably placed include laboratories, mechanical rooms, kitchens, and areas with flammable liquids are stored.

CO2 extinguishers are not recommended for Class A fires involving flammable solids as it is unlikely that it will be able to displace enough of the oxygen, so the fire could just re-ignite. For that reason, CO2 fire extinguishers are also not recommended for outdoor fires. At the opposite end of the spectrum, this type of extinguisher is also not recommended for fires in confined spaces, as the oxygen depletion could cause asphyxiation in the operator.

How to Use a CO2 Fire Extinguisher

Before operating a CO2 extinguisher, the user must move the discharge horn upwards until it is at a right angle with the canister. The horn itself should not be held during operating as the release of the gas could make a metal horn so cold a human hand will freeze to it.

When releasing a CO2 fire extinguisher, always aim the gas at the base of the fire where the gas is being released in order to have the maximum effect. The release of CO2 will also be very noisy.

Like all extinguishers, CO2 fire extinguishers should have a regular visual inspection and also be serviced on an annual basis. Unlike most other types of extinguishers, CO2 canisters will also need to have an overhaul once every ten years.

A basic maintenance schedule for a CO2 extinguisher involves checking to see if the extinguisher has been used, if it is damaged, that instructions are still legible, and that all exits on the canister are not blocked. An overhaul is more in depth as it involves a test discharge and a pressure test of the shell of the canister.

Fire Extinguisher Colors

Identifying and understanding the various fire extinguisher colors available can sometimes be challenging. The regulation for fire extinguishers (BS EN3) dictates that all extinguishers must be color-coded according to the fire-suppressing agent within them. Previously regulations stated that the whole body of the canister would be colored, however in the 1990s EU changes to this meant that newer extinguishers are bright signal red with a second band of color corresponding to the type of agent inside, covering between 3-5% of the surface area of the canister. This band must be situated on the top half of the canister and be visible from 180 degrees.

Fire extinguishers in the old style of a solid color canister are still legal; however they must be replaced in the new style as they reach the end of their life.

The purpose of having different fire extinguisher colors is so that in an emergency an individual can differentiate between the types and find it easier to use the correct one. All fire extinguishers must be visibly placed with their labels clearly showing, and positioned in such a way that the carrying handle is also easily accessible. Additional fire signage should also be located next to the extinguisher itself, with the detail of the type along with the same color coding label on the signage.

Since color coding alone is not as simple as it once was, standard pictograms are also present on the extinguisher canister to illustrate the class of fire that the extinguisher is suitable to combat.

Fire Extinguisher Colors & Fire Types

The types of extinguishers and their respective colored bands are as follows:

- Water – Red

- Foam – Cream

- Dry Powder – Blue

- Co2 – Black

- Wet Chemical – Yellow

- Halon – Green

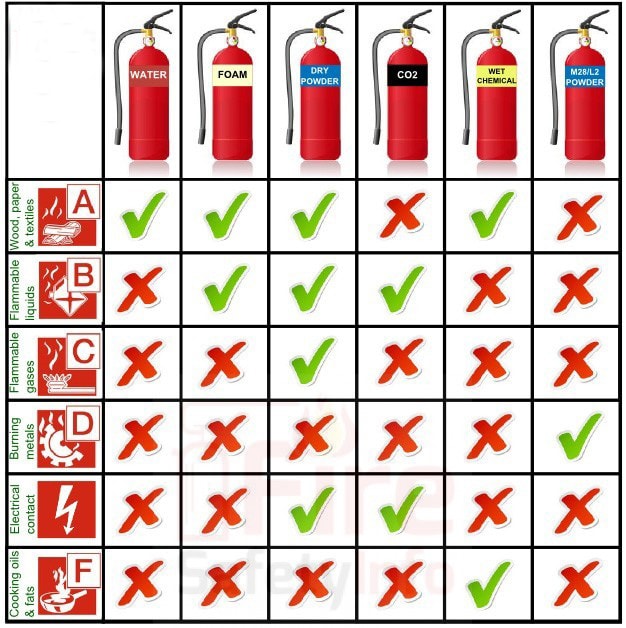

The chart below shows the available extinguisher colors and on which types of fires they can be used.

Please note: Powder extinguishers will leave a residue that can damage electrical equipment. If available, use a Co2 extinguisher instead.

Water extinguishers should never be used on a live electrical fire due to the risk of electrocution.

Fire Extinguisher Servicing

The main relevant piece of legislation regarding fire extinguisher servicing is contained within British Standard 5306-3:2009 – Fire Extinguishing Installations and Equipment on Premises. Commissioning and Maintenance of Portable Fire Extinguishers. Code of Practice. This legislation has several requirements for an employer or landlord supplying fire extinguishers in their properties.

Firstly, visual inspections of all fire extinguishers should be carried out on a regular basis, at least monthly. A visual inspection is a straightforward check to make sure that the extinguisher is present where it should be, that the extinguisher is both unused and undamaged, that it has not been tampered with, can be seen and reached, that the usage instructions are still legible, and where applicable that the pressure gauge is within the right limits. These visual inspections should be suitably recorded and dated.

A basic annual service must also be carried out. The requirements of a basic service will vary according to the mode of operation (either stored pressure or cartridge) and the type of extinguishing agent inside.

Stored pressure extinguishers are pressurized containers, where the extinguishing agent is expelled once the pressure inside is released by the operating trigger.

These types of extinguishers are usually water, foam, wet chemical and powder type extinguishers. The basic servicing regime is the same for all stored pressure extinguishers and comprises the following checks (summarised from Table D.2, Annex D of BS 5306:3), which should be carried out in this order:

- Check the safety clip and indicators to see if the extinguisher has been used.

- Check the pressure. This is simple if the extinguisher has a gauge fitted, but for those that do not, a special connecting device should be used to test it.

- Inspect the canister for damage e.g. corrosion, dents. Replace if necessary.

- Weigh the extinguisher (if more than 10% has been lost, a full recharge is required).

- Check that the operating instructions are legible and correct.

- If the operating head can be removed without discharging the instruction, this should be done and the mechanism checked and lubricated if needed.

- Remove and replace the safety pin, checking that the operating lever is undamaged and moves freely.

- Check that the hose, discharge horn and nozzle are not blocked and are undamaged. Replace the seals for these.

After this the extinguisher should be reassembled, and a written report should be compiled to detail the state of the unit. A label should be present on the canister to date the most recent inspection and the date of the next extended service.

Carbon Dioxide extinguishers vary slightly from the other types listed above as pressure is not tested here. All the other inspection points remain valid however.

Cartridge operated extinguishers are different in that the propellant is not located with the extinguishing agent but is located in a separate cartridge, which is pierced when the trigger is compressed, releasing the extinguishing agent.

Water and powder agents can commonly be found as cartridge types (as well as stored pressure types). The basic service is the same as outlined above, except the pressure check is not relevant so it is not carried out. The following additional checks are also made:

1. Open the extinguisher, remove the gas cartridge, and then:

- For water extinguishers, pour out the contents from the body and check the interior for signs of corrosion. The original charge may be re-used after inspection if the liquid is still good, if not, replace with fresh.

- For power extinguishers, check the powder for caking or lumps and recharge if necessary. Check the interior body for corrosion.

2. Check the operating mechanism moves freely and that the air passages are unobstructed.

Additional Fire Extinguisher Servicing Requirements

In addition to the annual basic service required as part of fire extinguisher servicing, Halon and Carbon Dioxide extinguishers should have an overhaul once every ten years, and a more in-depth extended service should be carried out on all other types of extinguisher once every five years.

An extended service involves an actual test discharge of the extinguishing agent, and an overhaul involves both a test discharge and a pressure test of the shell of the canister.

Fire extinguisher servicing is best carried out by a professional external company that is suitably qualified to do the job. When seeking to employ a professional company always look for BAFE accreditation (the British Approvals for Fire Equipment, the independent registration body for companies wishing to achieve third party certification in fire protection, which proves a high competency level in fire extinguisher service and maintenance that is in line with the Regulatory Reform (Fire Safety) Order 2005.